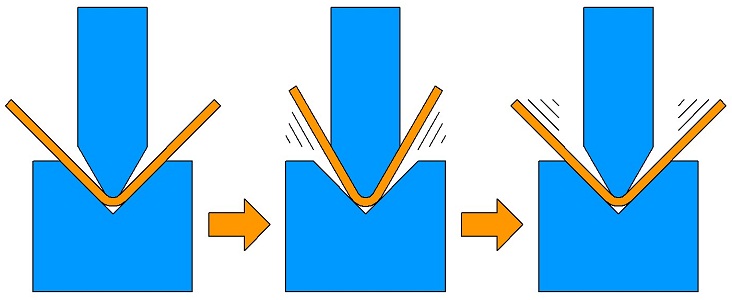

Bottom bending is the process of stamps the radius of the punch tip into the work piece. This differs from Coining, which puts the entire surface of the work piece under such tonnage that it begins to flow. when Bottom Bending the die angle should match the intended angle of the work piece, adjusting a few degrees for Spring Back, hence the existence of 88 ° punch tooling to achieve 90 degree angles. The workpiece is first bottomed against the die, then the radius of the punch is forced into the work piece which achieves the angle of the punch, it is then released and the workpiece springs back to meet the die again.

In order to compensate the angle of the punch can be smaller than the angle of the die by a few degrees allowing an over-bend when the punch tip is forced into the workpiece, it should not be larger or else you will damage the tooling. This method can give an operator excellent repeatability if properly set up. Setting up a Bottom Bending operation accurately requires knowledge in the tooling, material, tonnages and even the timing of the different steps so it lends itself to a more skilled operator.

Bottom bending is often confused with Air Bending, and leads operators to ask themselves why there is a difference in radius when bending a 90 ° and 80 ° angle. This is because when bending the 80 ° the punch tip is not pressed into the sheet metal in the way Bottom Bending is.