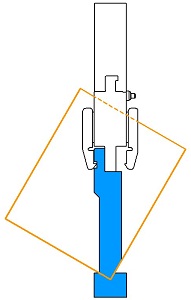

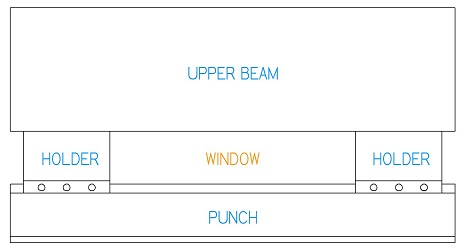

Box bending can be rather tricky with sheet metal because of the geometry of a press brake. typically the upper beam or punch holder will get in the way of very deep boxes. When bending with large returns there are a few tricks outside of just tooling selection. When bending a 2 sided box, with only a bottom, front and back, it is possible to remove a section of the holder and let the punch for a bridge. This process known as window bending is not recommended for anything other than relatively short flanges. The punches will not have the resistance to crowning that an upper beam will have. This could result in poorly bent pieces or damaged tooling. With all of this in mind window bending can be advantageous in some situations. Window bending does not however help with 3 or 4 sided boxes. There are some types of 3 sided boxes which can be bent by ‘hanging’ the work piece off of the end of the brake, allowing the 3 bend to clear the upper beam because it is to the side of it. This method could be made difficult depending on the layout of your Brake Press; often controls are placed on the side of brakes which can interfere. In addition to this if there are other machines to the side of the brake they can also cause interference.

Most 3 sided and all 4 sided boxes will require sectionalized tooling to get into the box. As we talked about above the main challenge is the upper beam. This can be mitigated by a few methods of tooling selection which we will discuss below. Before pulling the trigger on new tooling be sure to analyze the geometry you are trying to bend and see if there isn’t some other way around having to form a deep box. One common method that I’ve seen used is slitting the last bend by putting a perforation along the bend line. The first 3 bends are created and then the fourth is performed by hand. While less precise than a press brake bending the part by hand can be quick and cheaper than new tooling. The first example is bending a box without special tooling. Knowing your tooling geometry will allow you to know ahead of time whether your design is going to work. A common mistake by new engineers is not to know what the geometry of the upper beam and press brake is going to be. I’ve see many, many press brakes which had decorative panels removed from the upper beam to allow for more clearance, so be sure to check the machines in your shop before assuming anything.

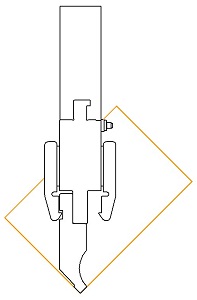

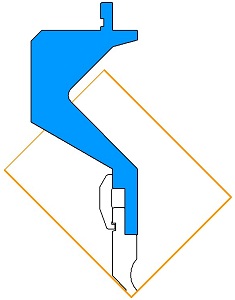

Extreme Goose Neck Tooling

The first example of a tooling solution is fundamentally the easiest to understand. Many tooling manufacturers will offer at least one ‘extreme’ style goose neck punch. many tooling houses will also be able to manufacture a customized set of tooling for you if the cost is justified. The size of this tool can be intimidating, but it gets the job done. The relief on these tools allow very deep boxes to be formed by eliminating the interference of the upper beam. There are some disadvantages to this type of tooling, they are very heavy and expensive to replace. If you need to have the tooling custom made it can be rather expensive.

Goose Neck Punch Holder

Offering more flexibility than a simple goose neck punch a goose necked punch holder can be fitted with any punch offering versatility for the inside bends. This can be especially useful for adding a radius or other feature to the inside bend. While it suffers from the same problems as large goose neck tooling such as expense and weight it does offer the added flexibility of choosing the punch tip.

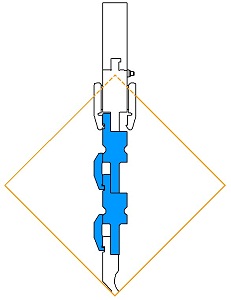

Stacking Punch Holders

Many tool makers will sell specially modified punch holders which are meant to stack on top of one another. Stacking these holders with a punch tip offers the versatility of a goose necked punch holder while eliminating the problem of weight. While still expensive the individual pieces can be more easily replaced if they are damaged. Imagine the cost of replacing a section of the previously mentioned tools. Staking punch holders will also allow you to work with your press brake’s stroke height.

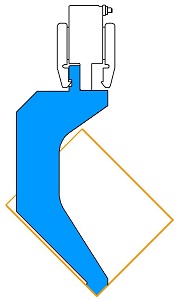

Deep Box Bending With 30 ° – 60 ° Tooling

One unusual method for deep Box Bending is to use tooling which is offset 15°, creating a 30° – 60° punch and die combination. By offsetting the bend orientation you can gain significantly more room to close your box. The important thing to understand from a tool engineering stand point is that the pressure angle is no longer 0° like it is with conventional tooling. This means you need robust tooling, and your tonnage charts go out the window. Consult with your tooling manufacturer, as well as the manufacturer of your punch holders before taking advantage of this tooling. With this said, once you’re sure this type of tooling will work it offers a good deal of versatility and functionality. It’s not over heavy or unruly, like the large goose neck types.