Spring back occurs when a metal is bent and then tries to return to its original shape. There are two basic views as to why Spring Back occurs, one states that it is due to the displacement of molecules and the other considers Spring Back in terms of a stress-strain diagram. One of the reasons for Spring Back is that as the material is bent the inner region of the bend is compressed while the outer region is stretched. This means that the molecular density is greater on the inside of the bend. generally the compressive strength of material is greater than it tensile strength. This means that pressure will permanently deform the outer regions of the piece before it deforms the inner regions. The compressive stress is changed into Spring Back.

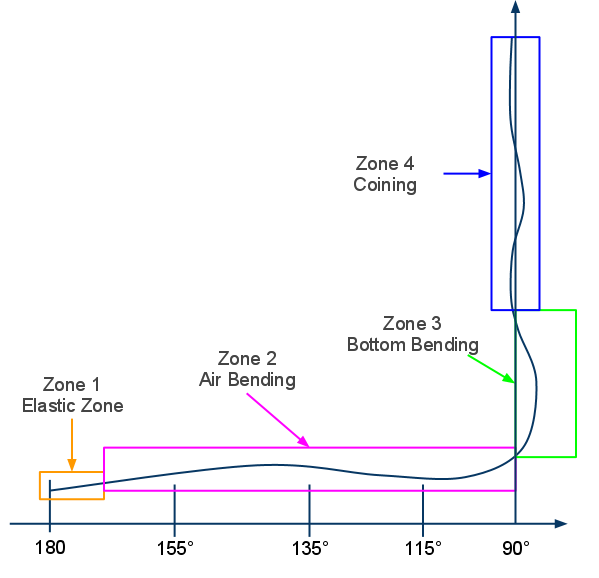

To the left is a general example of a stress-strain diagram showing how it relates to the different types of bending and Spring Back.

In Zone 1 the material is elastic, meaning that if it is bent it will return to its original shape without any permanent deformation. Eventually the material reaches its yield point and permanent deformation of the metal will occur.

Zone 2 shows that as the work exerted on the sheet metal increases the metal begins to bend, however in this region it will return slightly. The amount that it returns is a property of the metal as well as the tooling used to bend it.

In Zone 3 the material hits the bottom of the die and experiences a brief stage of negative Spring Back or spring forward. This is also a property of the metal but can be as significant as a few degrees of overbending past 90 °.

As the force increases significantly in Zone 4 the material begins to average between spring forward and Spring Back eventually undergoing the process known as Coining where there is no Spring Back.

Compensating For Spring Back

When compensating for Spring Back in materials such as stainless steel Coining is typically not the best option unless you are working with thin gauges. The required tonnage is often prohibitive. Instead Bottom Bending can be preferable offering a higher degree of control however even this can prove a challenge. Differences in sheets, even within the same batch, can contribute to fluctuations in bent angles. Air bending when combined with modern CNC Brake Presses can offer a good amount of Spring Back compensation, especially when bending with 75 ° tooling. The deeper tooling allows you to over bend 15 ° (on a 90 ° bend) without limiting your tooling options the way most acute tooling does. To achieve a perfect bend it may be necessary to work with feedback mechanisms. Typically these systems use lasers to track Spring Back on a piece as it’s being bent and adjust in real time for each piece. Generally the best way to conquer Spring Back even in difficult materials such as stainless steel and aluminum is to train your operators to perform check bends and adjust their machines for each setup. Providing an operator with standard sized strips of varying gauges will allow them to adjust tonnage and gauging for each setup without failed pieces.

Calculating Spring Back

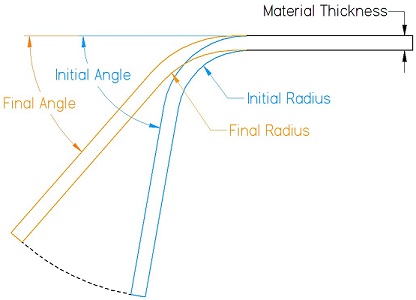

The spring bacK-Factor, commonly denoted by Ks, is the relation between the initial and final angles. A spring bacK-Factor of Ks=1 means there is no Spring Back, where a value of 0 means total Spring Back.

To calculate the spring bacK-Factor ahead of a test piece it is important to understand that the bend radius is affected as well as the angle. The radius of the bend will try and return in the same way the angle does meaning the initial radius (I.R.) will be slightly smaller than the final radius (F.R.). This relationship can also be used to define the spring bacK-Factor.

Taking this one step further we can incorporate the yield stress and elastic modulus into our calculations. A higher yield stress leads to greater Spring Back and a higher elastic modulus leads to less Spring Back.

Designing With Spring Back

It is important to understand the difference between the bending angle and the bent angle. When designing it is easy to become concerned with the finished, or bent angle. This consideration of only the finished bend can lead to mistakes in design. When fabricating the Brake Press operator will have to bend your part past the intended angle so that after it springs back he or she has reached the correct angle. If your design does not allow for over bending of interfering flanges it could lead to a failed design.