Skip to content

Formulas:

Formulas:

- Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length.

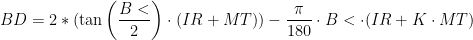

- Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern.

- Material Thickness (MT) – The gauge of the material in decimal form.

- Bend Angle (B<) – The inside angle between the two legs or flanges of a bend.

- K-Factor (K) – The ratio of the position of the Neutral Axis to the Material Thickness.

- Y-Factor (Y) – A constant based off of the K-Factor used by Pro-Engineer in place of a K-Factor.

- Inside Radius (IR) – The final formed inside radius after spring back has occurred.

- Outside Radius (OR) – The final formed outside radius after spring back has occurred.

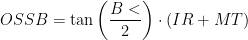

- Outside Setback (OSSB) – Distance between the outside tangent points and the apex of the outside mold lines.

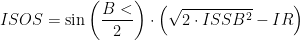

- Inside Setback (ISSB) – Distance between the inside tangent points and the apex of the inside mold lines.

- Outside Mold Line (OML) – A line that runs parallel to the outside of the workpiece.

- Inside Mold Line (IML) – A line that runs parallel to the inside of the workpiece.

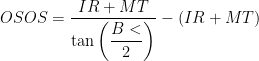

- Outside Offset (OSOS) – The measurement from the surface of the outside radius to the apex of the outside mold lines. When calculating the outside offset use the included bend angle.

- Inside Offset (ISOS) – Distance between the inside mold lines and the bend line.

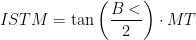

- Inside Through the Material (ISTM) – The distance between the outside and inside mold lines.

- Inside Shift (ISS) – Distance between the outside mold lines and the bend line.

- Bend Line Shift (BLS) – The distance from the Outside Mold Line to the original bend line on the flat pattern. This is used to calculate the back stop location when working off of a flat pattern.

Terminology

- Air Bending – One of the three types of bending for sheet metal where the outside mold line is not pressed against the die.

- Air Bend Force Chart – A chart used to calculate the tonnage required for a bend based on thickness, tooling and length.

- Annealing – Annealing is a treatment for metals where a material is heated above the recrystallization temperature maintained for a period of time and then cooled. Annealing is used to soften material, relieve internal stresses and improve its cold working prope

- rties.

- Bending – The process of cold working metal to achieve a desired profile.

- Bend Line – The line across the metal where the punch comes in contact with the metal and the bend begins.

- Bump Bending – Also known as Step Bending, the process for forming a large radius with conventional tooling by performing a series bends in close proximity.

- Blanking – The process of cutting flat patterns from stock sheeting, done typically with lasers, water jets, plasmas or punch presses.

- Bottom Bending – One of the three types of bending for sheet metal where the radius of the punch tip is pushed into the sheet metal.

- Box Bending – The process of bending a 4 sided sheet metal box.

- Coining – One of the three types of bending for sheet metal where the punch penetrates into the sheet metal under high tonnage forming a consistent bend.

- Cross Break – Light bends added to sheet metal in order to stiffen its surface.

- Crowning – The deflection along a bend due to the tooling or brake not being able to apply equal tonnage along the bend. Crowning is controlled on modern brakes with internal hydraulic systems which can help equalize pressure.

- Curling – A forming process which leaves a circular, closed loop at the end of the sheet. This forms a safe edge for handling and stiffens the part’s edge.

- Flange Length – The length of the workpiece when measured from the apex to the edge of the bend.

- Flat Pattern – The general term for the unfolded, flattened, geometry of a part.

- Foil – Very thin sheet metal made from typically malleable metals such as aluminum and gold.

- Gage, Gauge – The thickness of the metal organized by numbers, the larger the number the thinner the metal.

- Galvanneal – Steel which has been galvanized and then subsequently annealed.

- Galvanized – In order to prevent rust steel is dipped into molten zinc which alloys itself with the surface of the steel.

- Gusset – A section of the metal inside a bend which is not bent, but rather

forced into the bend in order to stiffen the piece.

- Hem – A flange that reaches 180° or more. Hems can be flattened, left open or in a variety of tear drop shapes.

- Jog – Also known as an offset bend, this is when two bends of the same angle, but opposite direction, are used to create a ‘z’ shaped profile.

- Kink – A light bend typically between 5° and 15° which is used to stiffen a flat piece of metal.

- Large Radius Bending – Also known as R Bending, large radius bending is when the inside radius is greater than 8 times the material thickness.

- Leg – Length of the workpiece from the edge to the outside tangent point of the bend radius.

- Neutral Axis – An imaginary line within the bend where the material goes through no compression or stretching during the bend process.

- Obtuse Angle – A geometry term for an angle which is greater than 90°.

- R Bending – Bending with an inside radius greater than 8 times the material thickness.

- Reflex Angle – A geometry term for an angle which is greater than 180°

- Sharp Bend – When the radius of the bend is less than %63 of the material thickness, seen commonly with hemming applications.

- Spring Back – The amount to which the workpiece resists bending by returning to its original shape.

- Step Bending – Also known as bump bending, the process for forming a large radius with conventional tooling by performing a series bends in close proximity.

- Straight Angle – A geometry term for an angle which is equal to 180°.

- Tolerances – General dimensioning and tolerances of bends and sheet metal.

- Tooling – General term for the dies, punches and holders found on press brake equipment.

- Work Piece – The general term for the sheet metal part being bent.

Back to Top

Formulas:

Formulas: