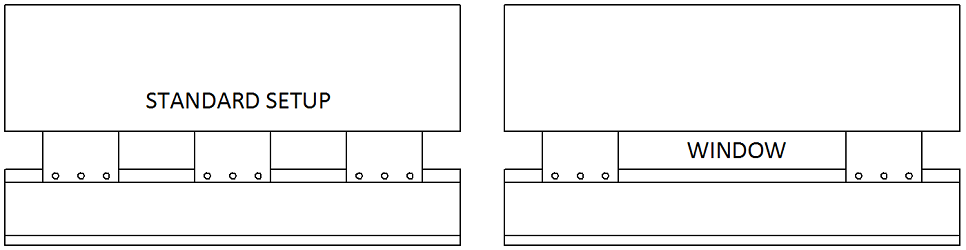

A window punch is a creative solution for bending very deep draw channels and other parts which require an initial bend to pass through the area typically occupied by the punch or punch holder. If this type of bend is attempted with normal tooling you risk severe back bending and part damage. Incorporating a window punch into your setup has the potential to allow you to bend these geometries. This setup is achieved by spanning the punch tooling between holders, which allows you to form above the punch.

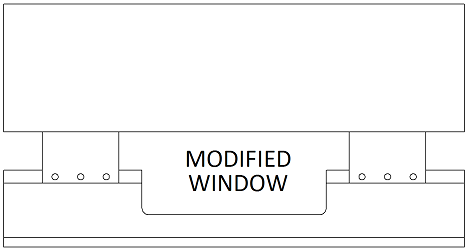

In addition to simply removing a holder it is possible to purchase custom tooling, or modify your own tooling to extend the punch. be sure to always use the most robust tooling possible when doing this and consult with your tooling manufacturer before hand. This type of bending should always be performed with care.

Tonnage

Considering the tonnage required for the bend will be the first step to creating a successful window punch. It should be no surprise that the suspended punch is weakened by lack of support from the holder and is thus prone to crowning or damage. This means that Coining is out of the question, and Bottom Bending should only be considered with great care. Air bending should be your first consideration when engineering this type of set up. In addition to this the opening size of the window should be minimized as much as possible. While it will be necessary to leave some clearance for the part it should only be enough for the flange to clear. Any features that may increase or decrease the width of the flange should be performed after or before the window bend. In addition to all of this consider the design implications of a larger bend radius. If it is acceptable a larger die, with a larger bend radius, can reduce the required tonnage significantly. Once you’ve settled on a tonnage it is time to refine your tooling setup.

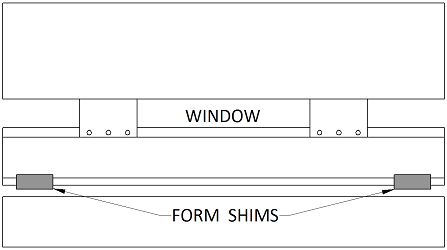

Shimming Under the Window

Crowning occurs when the tool or Brake Press gives slightly during the bending process. This give reduces the tonnage in the center of the bend compared to the edges where it is better supported. The effect of crowning is going to be more significant than that of a regular bend operation because you are no longer backing your punch with the upper beam. Now all of your crowning forces are focused on the punch itself. Without any compensation crowning results in an inconsistent Bend Angle across the work piece. The easiest form of compensating for small amounts of crowning is to place a shim underneath the die in line with the center of the window. Depending on your v opening a few pieces of paper will be enough to compensate for the crowning. Form shims, which are typically small pieces of the same material you are bending, can be added to the area of the punch outside of the window. These will provide support for this section of the die at the bottom of the bend, evening out the crowning across the whole length. See our post on Shimming for more information and techniques for shimming your Brake Press.