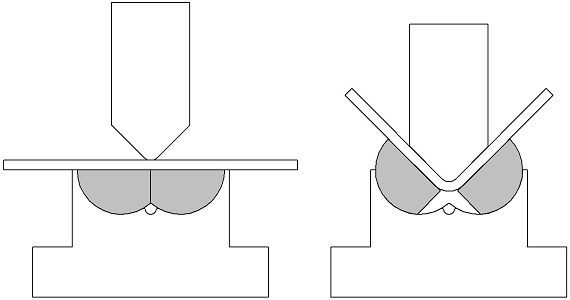

The Rolla-V Die is a specialized die which two semicircular rotating pads set inside the top of the die. As the punch moves downwards the work piece begins to bend and the pads rotate with the work piece. Below you can see the basic setup of a Rolla-V die. I’ve seen the Rolla-V name advertised as a patented technology, but have been thus far unable to locate the patent. There are a few models available from different manufacturers, as well as adjustable models.

The Rolla-V tooling style is able to support the work piece along a significant section of the outside mold line compared to a regular v die which only supports the work piece at a single point. This gives the Rolla-V type dies a few significant advantages:

Minimal distortion from cutouts and holes near the bend line. Typically a rule of two times the material thickness plus the bend radius is used. With Rolla-V dies you can get right up against the minimum flange length without any trouble.

Because of the design there is very little sliding of the work piece over the pad’s face. This virtually eliminates die marking which a problem for highly polished materials is. With Rolla-V dies you can create hems and bends free from markings, improving the overall quality of your product and eliminating the need for secondary polishing and cleaning operations.

Additionally the minimal sliding prevents material contamination between the die and the work piece. This prevents die contamination from Galvanize and Aluminum as well as part contamination on stainless steel work pieces.

The added support means that much smaller flanges can be formed compared to standard v opening dies. For example, according to our Air Bend Force Chart the minimum flange that can be obtained for 14 Gauge (.075”) is .281”, a Rolla-V die can form a .185” flange on the same material. That’s a 34% improvement.

Rolla-V dies can also handle a wider variety of gauges compared to v dies, which allows for fewer setups when changing between materials and thicknesses.

Adjustable models allow for extremely versatile bending of both sharp and large radius pieces further improving their versatility. Imagine being able to do a single stroke U bend with the same tool you bend 90° bends with. For a shop on a limited budget a few sets of Rolla-V dies can set you up to bend a very wide variety of geometries.

Media

I’m including a video which does a nice job of taking you through some bend operations that the Rolla-V style tooling is capable of.